Our company can customize 4 different toilet partition boards, namely compact laminate, PVC board, density board, and aluminum honeycomb board. They are made of different raw materials, so their properties are also different. The classic color is gray and white, and various solid colors and wood grain colors can also be customized.

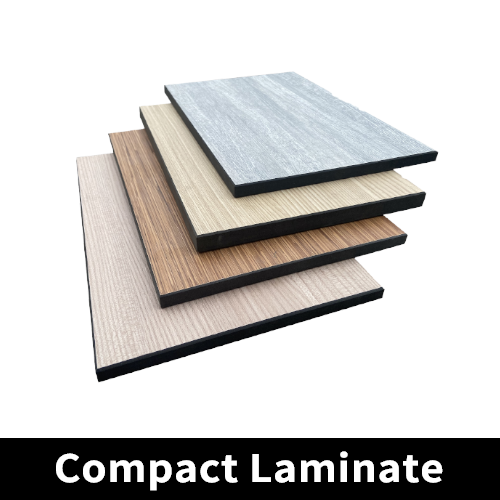

Compact laminates are made of decorative paper and kraft paper impregnated with melamine resin as the main raw materials, impregnated with phenolic resin, laminated, and then pressed in a high-temperature and high-pressure environment. It is a high-pressure decorative panel with a transparent structure. The colored paper layer on the surface can meet the decoration needs of various colors. It is light-resistant and high-temperature resistant, moisture-proof, waterproof and corrosion-resistant, and the surface is easy to clean and maintain.

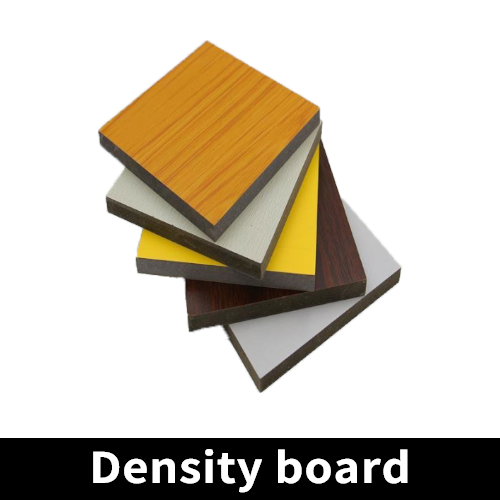

Density board is a wooden basic material made from joinery shavings as the main raw material and processed under high temperature and high pressure. MDF has the following characteristics: Light weight: MDF has a lighter specific gravity and is suitable for use in construction, decoration and other fields. Nowadays, more and more markets are devoted to the use of public toilet partition boards. High strength: The density board is processed at high temperature and has good strength and stability. Moisture-proof and waterproof: The surface of the density board has undergone strict waterproof treatment, and the board core can effectively prevent moisture and corrosion. Easy to process: MDF is easy to cut, cut and engrave, and is one of the commonly used materials for bathroom partitions.

Aluminum honeycomb panel is a composite material composed of upper and lower panels and an aluminum honeycomb core. The panels on both sides of the honeycomb aluminum panel are high-strength aluminum panels, and the inner layer is a special hexagonal aluminum honeycomb. Since the core panels are adhered to the sandwich structure, they are subject to tangential pressure. These dense honeycombs of mutual restraints are like many small I-beams. It can disperse and withstand the pressure in all directions of the panel, so that the panel is evenly stressed and ensures that the panel can maintain a high flatness even in a large area. This achieves many advantages such as high flatness, good sound insulation, good heat insulation and flame retardancy, and long service life. Generally suitable for bathroom use in mid-to-high-end places, such as restaurants, high-end shopping malls and other places.

Plastic steel plate is a composite material made of thermoplastic plastics and using hot melt welding technology. Features of plastic steel plate:

Has good corrosion resistance and heat resistance. Plastic steel plates can be used normally for many years at room temperature and are not affected by oxidation and corrosion. It is suitable for various corrosive media such as acid, alkali and salt; and has excellent high temperature resistance. Good waterproof performance, light weight, and easy installation: Compared with ordinary steel, plastic steel plates are light in weight, easy to install, low in cost, and have a long life. Some engineering bathroom partitions will also specify plastic steel plate materials.

Contact: Mr.ZENG & Mr.FANG

Phone: +86-15914954735,+86-13926407929

E-mail: hengli0308@gmail.com

Add: No. 27, Zhongxing Road, Jianggao Town, Baiyun District, Guangzhou City, Guangdong Province, China